The micro-targets that are used for high-power laser experiments conducted at the CLF and other facilities worldwide must be carefully assembled, often by hand rather than machine. The size and intricate nature of these targets, as well as the necessity for them all to be identical, makes it difficult to automate their production.

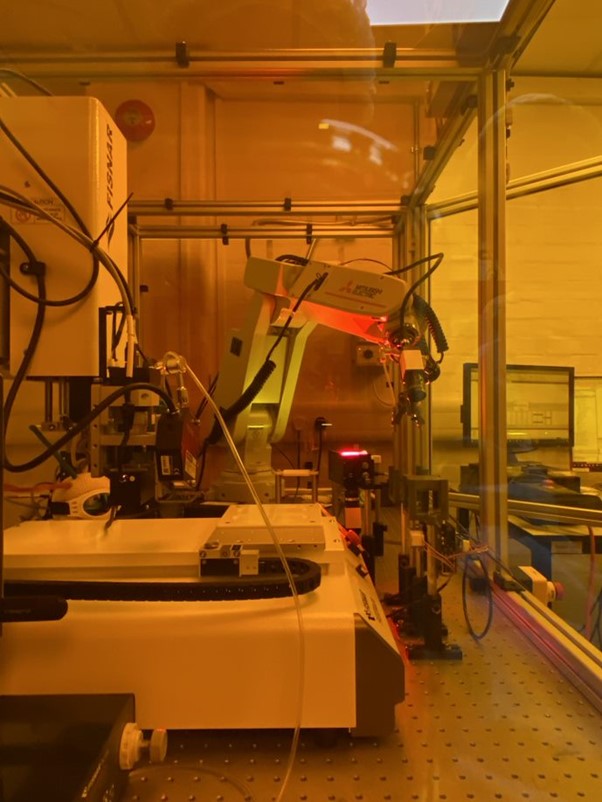

In recent years, lasers have become increasingly efficient and are able to operate at higher repetition rates, requiring far less time in between shots. This has resulted in a higher demand for targets in a smaller space of time – a single experiment can now require over a thousand targets! This demand makes it harder for target fabrication groups to keep pace with shot rates. Fortunately, this group are beginning to develop an answer: robots.

Target Fabrication's Array Assembly System, featuring their robots named Maxina and Thalia.

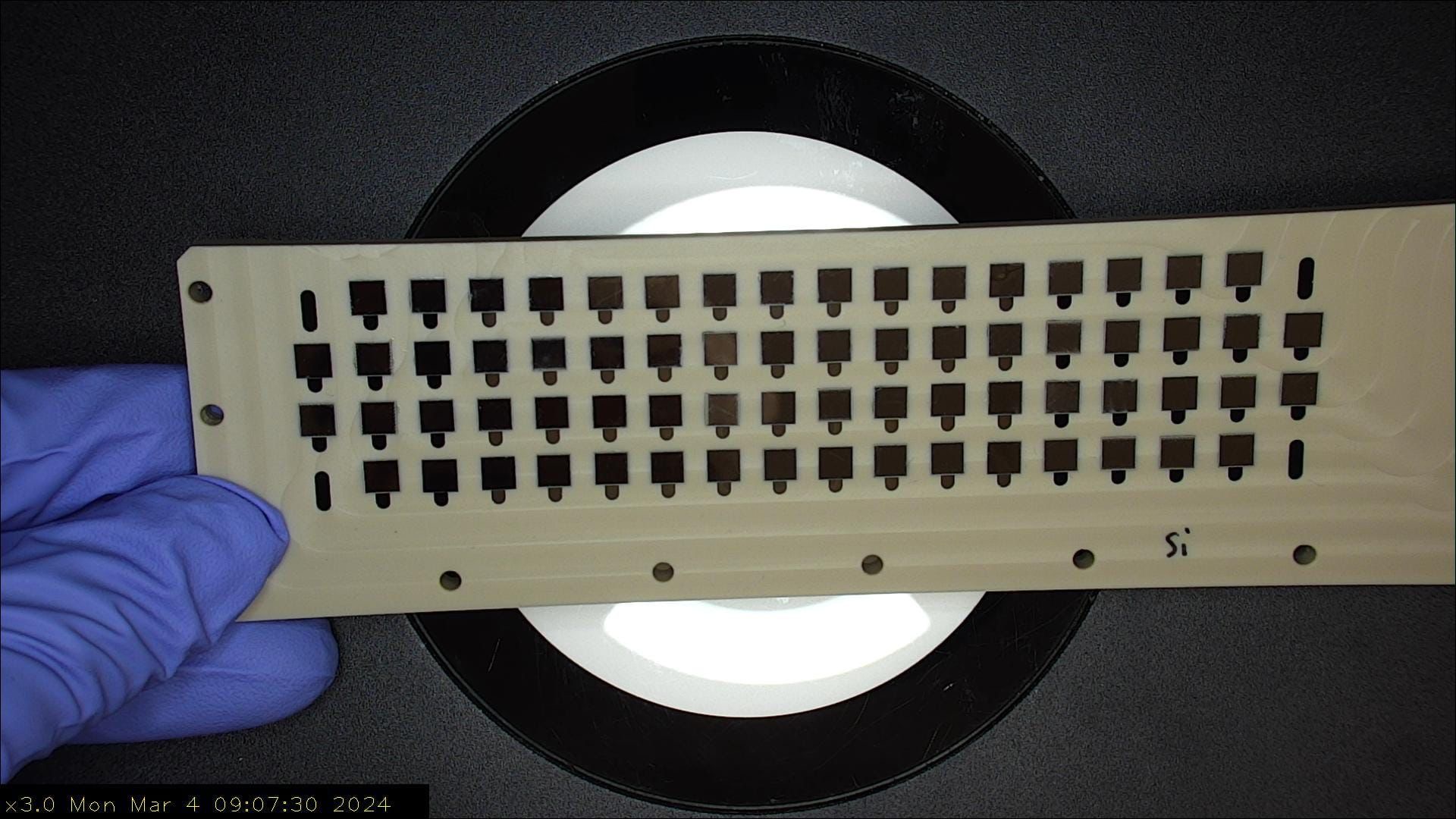

The targets shown are 4mm x 4mm in cross-section, and some are only 50 microns thick, which is roughly half that of a human hair. They are made of silicon attached to a layer of Kapton film, which is coated in aluminium. Each target is attached to a plastic array using a UV curing glue. The developing robotic system can carefully attach a simple target in under a minute.

.jpeg)

The robot creates targets in arrays of 64, as seen here.

Comparison to hand-made targets.

These targets are some of the first that STFC and Scitech have manufactured using a robot that will be used in a real-life experiment. It has been a highly successful project –creating ~800 targets, with not a single one being broken!